MIL-PRF-39006 App

| M39006 | / | 01 | - | 2237 |

| Basic Document Number | Specification Number | Dash Number |

Tantalum Dielectric

| Dielectric | K Dielectric Constants |

|---|---|

| Air or Vacuum | 1.0 |

| Paper | 2.6 - 6.0 |

| Plastic | 2.1 - 6.0 |

| Mineral Oil | 2.2 - 2.3 |

| Silicone Oil | 2.7 - 2.8 |

| Quartz | 3.8 - 4.4 |

| Glass | 4.8 - 8.0 |

| Porcelain | 5.1 - 5.9 |

| Mica | 5.4 - 8.7 |

| Aluminum Oxide | 8.4 |

| Tantalum Pentoxide | 26 |

What makes Tantalum a perfect dielectric for capacitors? It’s the oxide it produces. Almost all kinds of metals produce some kind of oxide when reacting with air. For example iron produces rust and copper produces a black oxide. Those types of oxides are referred to as crystalline oxides, meaning they are non-protective. Tantalum belongs to a group of metals called valve metals which include titanium, zirconium, niobium, hafnium, and aluminum. What makes Valve metals special is that they are able form a tightly adhering, stable, and electrically insulating oxides. However not all valve metals are able to have the thickness of their oxide accurately controlled through an electrochemical process.

Tantalum pentoxide possesses an extremely high dielectric constant of 26. When comparing a tantalum pentoxide to aluminum oxide you will notice a huge difference in dielectric constants. Both dielectrics are made from precious valve metals and possess the highest dielectric constants in the table. However tantalum pentoxide has a dielectric constant that is almost three times greater than aluminum oxide.

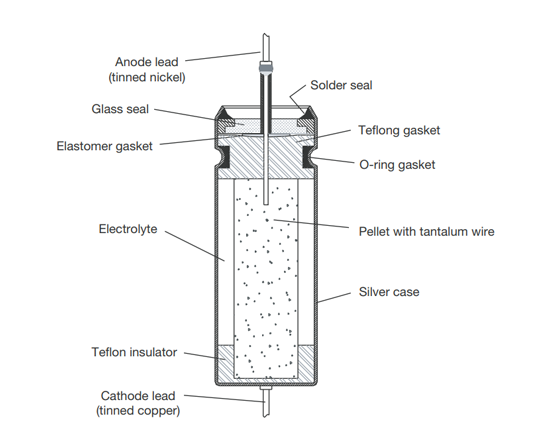

M39006/22/25/30/31

All Tantalum Hermetic Seal

Voltage Range:

- 6VDC - 125VDC

Capacitance Range

- 1.7µF - 2200µF

Primary Applications

Designed for heavy duty industrial and military utilization that demands filtering, energy storage, and voltage hold-up. This type of capacitor is highly resistant to damage from extreme vibration and shock. This series is excellent for use in aerospace, missiles, power supplies and "Down-Hole" oil exploration.

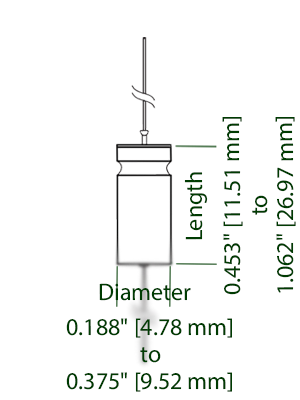

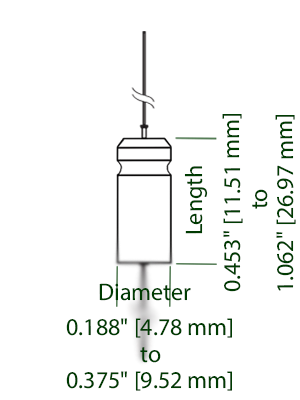

Size Range

M39006/09/21

Silver Case Hermetic Seal

Voltage Range:

- 6VDC - 125VDC

Capacitance Range

- 1.7µF - 2200µF

Primary Applications

Designed for utilization in heavy duty industrial and military equipment. This capacitor provides premium performance and high reliability with respect to low DC leakage current, high volumetric efficiency, and high inrush current capability are crucial.

Size Range

Technical Specification

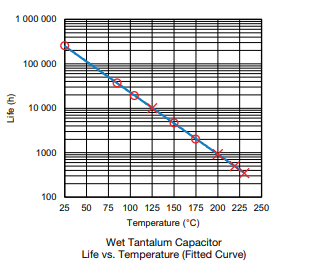

The military specification MIL-PRF-39006 establishes the failure rate testing per 1000 hours.

- 2%

- 1%

- 0.1%

- 0.01%

- 0.001%

The points on the graph marked with an “X” are fixed from ongoing reliability test data at +125 °C and above at the appropriate voltage derating.

Note: Any application above +85°C should be at a derated voltage suitable for the temperature.

| Maximum Operating Voltage | ||

|---|---|---|

| Rated (+85°C) VDC | Derated (+125°C) VDC | Derated (+85°C) VDC |

| 6 | 4 | 6.9 |

| 8 | 5 | 9.2 |

| 10 | 7 | 11.5 |

| 15 | 10 | 17.2 |

| 25 | 15 | 28.8 |

| 30 | 20 | 34.5 |

| 50 | 30 | 57.5 |

| 60 | 40 | 69.0 |

| 75 | 50 | 86.2 |

| 100 | 65 | 115.0 |

| 125 | 85 | 144.0 |

Click here to browse our Tantalum Capacitor inventory

Federal Connectors is a supplier of Military Connectors, Military Fuses, Military Potentiometers, Military Resistors, Military Relays and other electronic components to the US government and various subcontractors. Our team at Federal Connectors has been serving government agencies and industrial organizations throughout the electronics community for over 25 years. We provide our customers with an easy shopping experience and reliable fulfillment.